No products in the cart.

What is Pneumatics ?

Pneumatic systems are widely used in all sorts of machines, engines and industrial applications. Every pneumatic system runs on compressed air or gas, in order to move an actuator, and can be as simple as a single air-driven piston, or as complex as a mining operation with multiple actuators. Plain atmospheric air is the most commonly used for compression; there’s plenty of it, and in itself, it costs nothing. Pneumatic systems are generally preferred in industry and manufacturing over hydraulic systems, because they’re quieter, cheaper to run and easy to use.

Common Parts Of A Pneumatic System

The most common parts of a pneumatic system are:

- Drives/Cylinders

- Valves

- Fittings

- Tubing & Hoses

- Air Preparation (Filters, Regulators & Lubricators)

- Vacuum Technology

- Silencers

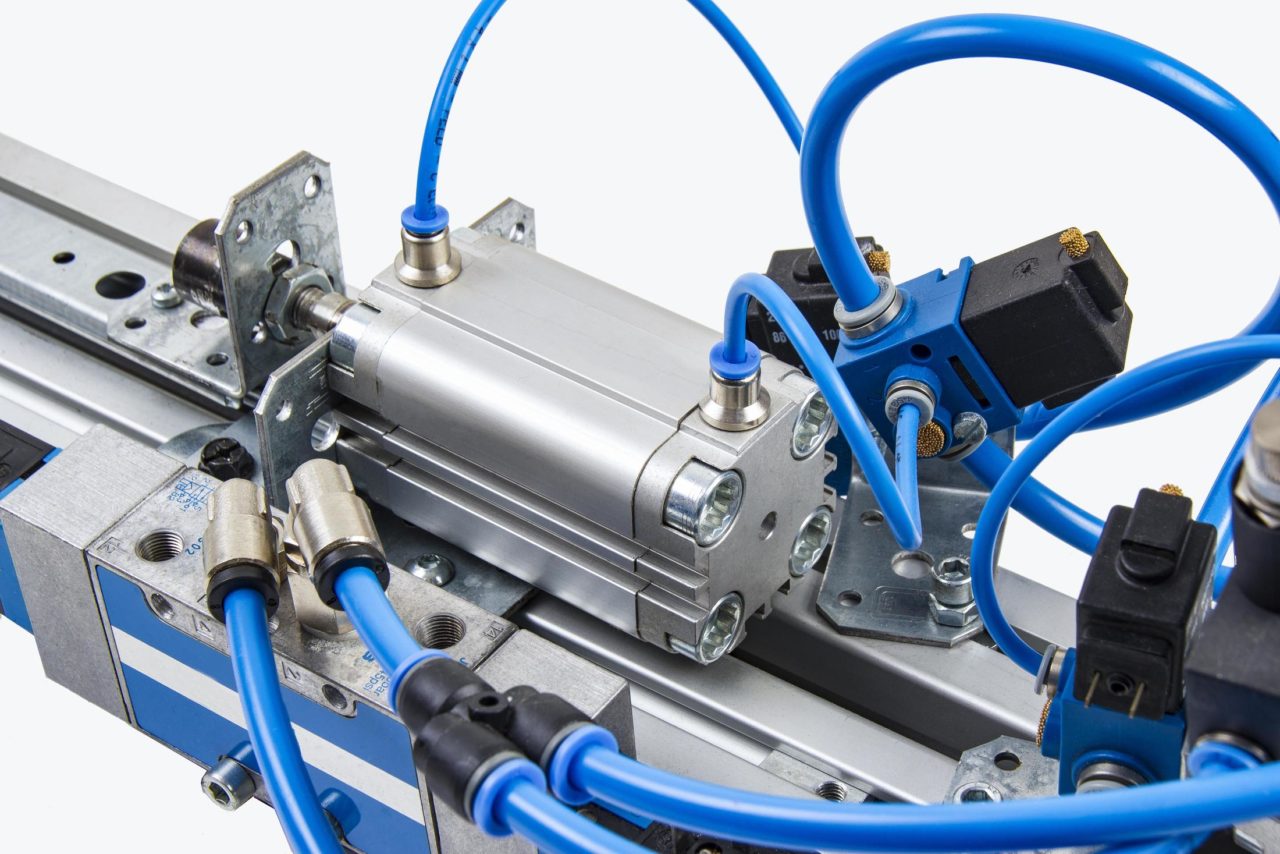

Drives/Cylinders

Pneumatic systems work by converting force into potential energy, which then drives an actuator or cylinder with kinetic energy. This is usually in a linear motion by means of a piston rod, or using other forms of actuation commonly called ‘rodless’. The piston rod produces a simple up-and-down or back-and-forth motion, and the rod can be pushed either via a single action or a double-action stroke.

In single-acting pneumatic cylinders the compressed air drives the linear motion of the piston rod in one direction only. At the end of the stroke, a vacuum is created by expelling the compressed air, so the piston rod can make the return stroke via a mechanical spring. Double-acting cylinders allow the load to work in a push-pull motion, manipulating the compressed air with valves to drive the piston rod out and back. This can increase the length of stroke achievable, as well as enabling constant force to be maintained on alternating movements.

Rodless cylinders work in several different ways, including linear slide, magnetic coupling, inflatable bellows and rotary vane pump. The load is usually situated on a carriage alongside the piston, and they are often chosen for applications requiring a long stroke action or having high moment loads.

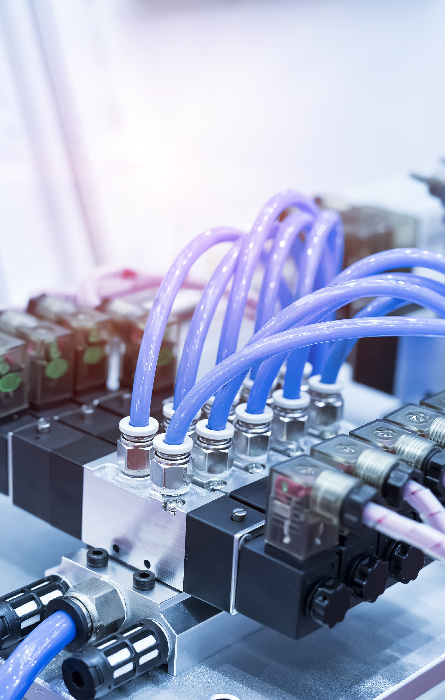

Valves

Valves are used in pneumatics to control and direct the airflow, and have many different functions. When you start up the system, you might use a soft start or a simple on-off valve, and you can control the rate of the airflow with flow control valves. For controlling flow direction, there are ball valves and angle seat valves, and you can use pilot valves to control a separate, secondary system.

When you need to vent the system you’ll use an exhaust valve. To close it down requires a shut-off valve, and to initiate an emergency stop you’ll need a safety dump valve. All these types of valve release the air pressure from the system at specified times.

Simple air valves control the inward and outward flow of air into the pneumatic system, requiring some motivating force to direct or position the flow. If this force is applied directly to the operating medium, it’s a direct-operated valve rather than a pilot or secondary valve. Other simple valves are the two-position flow control valves, which are either on or off.

Flow and directional control valves are self-explanatory, but there are also versions which allow three-way directional control from the inlet to either of two outlet ports, and the more complex four-way valve. This can direct flow from the inlet to a choice of three outlet ports. Proportional valves are electronically actuated using solenoids, and can alter the flow rate or pressure of the output in accordance with those of the inlet. This type of valve is used for more complex operations with one or more outputs, where fluid pressures and flow need to be distributed in varying ratios.

Fittings

Pneumatic systems comprise many components, and they all need to be joined together with fittings. Pneumatic fittings join together the major system components with their requisite hoses, pipes and tubes, conducting the compressed air to the active parts of the application. The whole system is operating under the pressure of compressed gas or air, so all its component parts require tight, leak-proof seals and must fit together compatibly.

Fittings come in all shapes, types and sizes, are made of various materials, and have different ways of joining together. Fittings that use metal screw-in threads are still considered to provide the tightest bond, though other materials like polymers are also now used. Pipes that are of different size or type may be joined using compression fittings, while barb fittings are often chosen to join flexible tubing. These have a threaded end which connects to the pipe, and a single or multiple barbed cone which goes into the tube. Many people prefer the modern solution of push-in fittings, which are often used for joining air hoses. Their quick connect and disconnect design enables the easy change-over of different parts, and they come in many sizes and materials.

Tubing and Hoses

Tubing and hoses in a pneumatic system are two different things: hoses are typically used in high-pressure applications and are reinforced for extra strength; tubing, on the other hand, tends to be used in applications requiring lower pressure, and does not need reinforcement. Both come in many different types, with flexible pneumatic tubing or hoses being more widely used than the rigid ones. The development of strong polymers and application-specific materials make flexible tubes and hoses the most versatile parts of a pneumatic system. All you need to do is ensure that you have the right size and type of hose or tubing for your devices, and that everything is compatible.

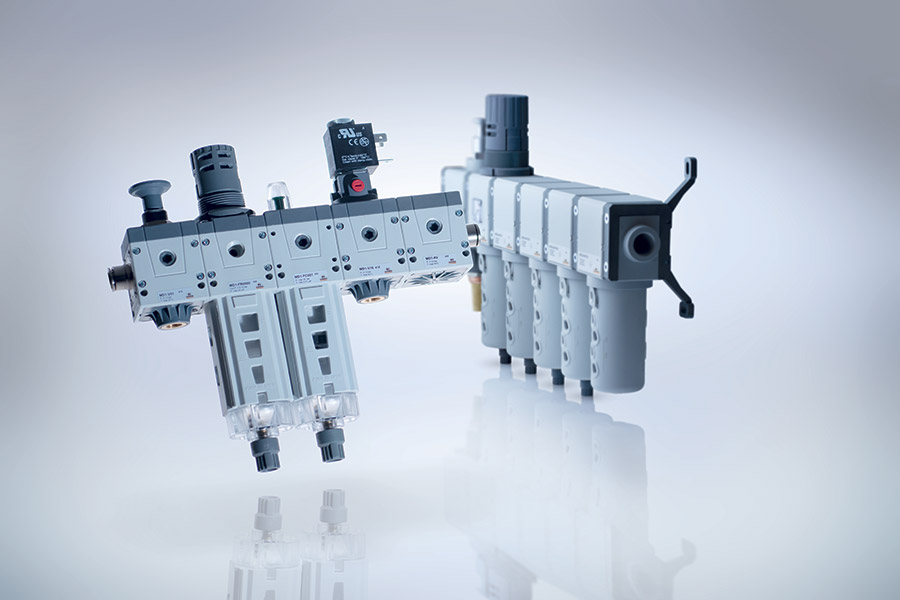

Air Preparation

When air is compressed it heats up, and when it cools again it produces condensation which contaminates the supply of compressed air. Ordinary atmospheric air also generally contains impurities such as dirt, dust, oil and other particulates. If compressed air containing such contaminants is passed downstream into functioning parts of the pneumatic system, such as cylinders, valves and hoses, it will inevitably cause some damage. Even if your compressor has built-in components for filtering, drying or regulating the air intake, fittings and components along its outward journey to the application can contribute further contamination.

In order to keep your system functioning properly for as long as possible, therefore, it’s necessary that the compressed air supply is filtered. It is possible to install a simple air filter for this purpose, but the air will still have to be monitored to make sure that the correct pressure is being maintained. Furthermore, the compressed air will need to be lubricated so that downstream equipment is not damaged by an excessively dry air supply. So while all these functions can be dealt with by separate units for filtration, regulation and lubrication, it’s more common these days to install a combined Filter-Regulator-Lubricator unit (FRL).

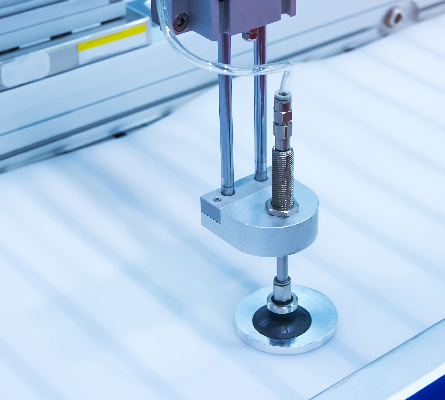

Vacuum Technology

Creating a vacuum produces conditions where the air pressure is substantially below that of atmospheric air, specifically a negative pressure of 300 mbar or less. The available vacuum range is then subdivided into four categories, ranging from rough to ultra-high vacuum. In order to create a vacuum, it’s necessary to remove all the air from a contained space, for which you can use a vacuum generator connected to your pneumatic system. This ejects compressed air forcibly through a diffuser, leaving a vacuum in the application. The item on the workspace will then be drawn up into the vacuum by means of a suction pad or cup, and gripped there while it is processed.

Many fields of modern industry and various manufacturing processes are now using vacuum technology, including food and beverages, pharmaceuticals, metallurgy and process engineering. They are typically used for delicate pick and place applications, such as plate glass and small electronic components, or for gripping and holding items in position. One of the most recognisable uses for this technology is vacuum packaging.

Silencers

Pneumatic air silencers, like the silencer on your car’s exhaust, are simply a means to reduce excess noise when air is exhausted from your pneumatic system. Venting the exhaust air from a pneumatic system often makes an explosive sound, depending on the force and pressure of the flow. This increases the operational noise levels of the application as a whole, and can cause physical damage or disturbance to personnel. Installing a silencer is a cost-effective solution which can be fitted on pneumatic cylinders, 5/2-way solenoid valves, or other associated devices and fittings.

In addition, silencers can manage the airflow rate out of the unit using adjustable throttle valves. These work in a similar fashion to needle valves and can also control actuator speed. Further, the exhaust air may also contain contaminants, so an exhaust cleaner may be added to the silencer unit to protect the environment from any harmful particulates.